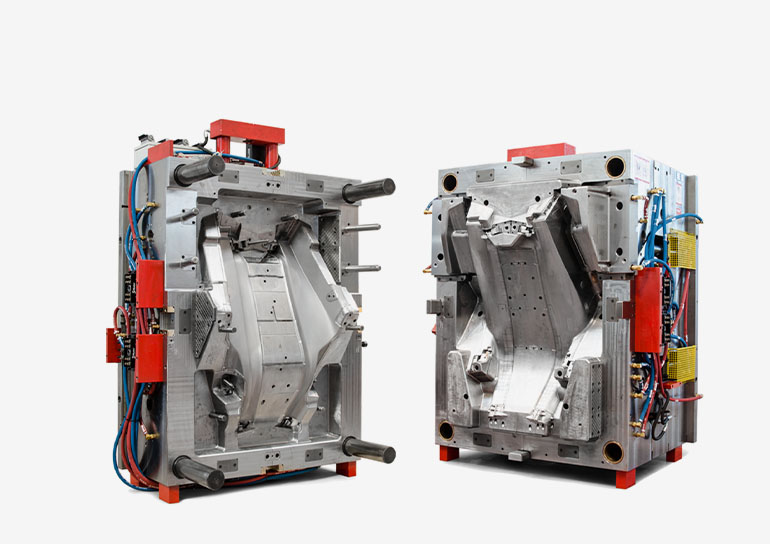

DRT Moldes offers a turnkey solution for every project. It all starts at the Design and Engineering Department, then a detailed Planning is made, whether the challenge is prototype tools or serial tools with different technologies. Our try-out center is prepared for internal try-outs or pre-serial productions. DRT Moldes intends to be always on Customer’s side, that is why we offer an After Sales service of excellence.

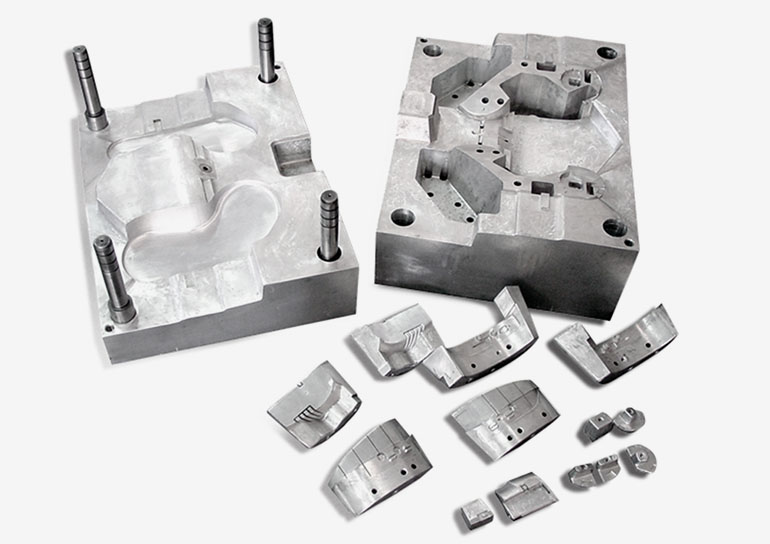

Moulds from 1Ton

Up to 35Ton

Fuel Tank

Airbag

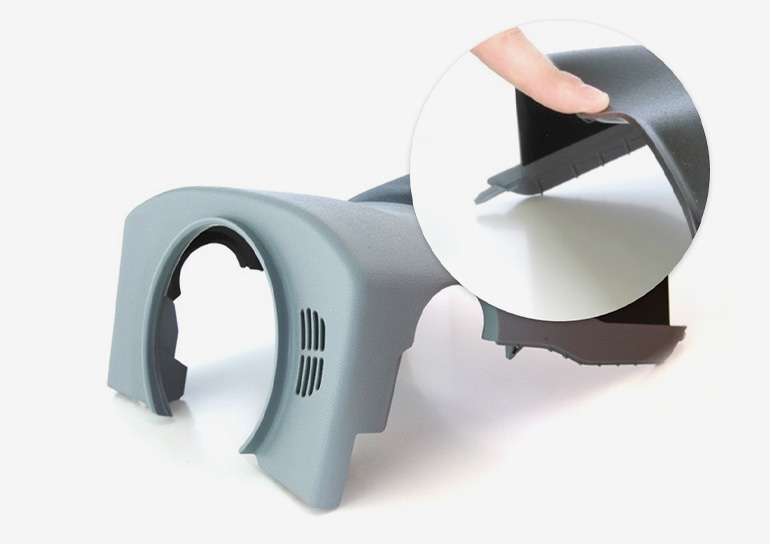

Windshield Cowl

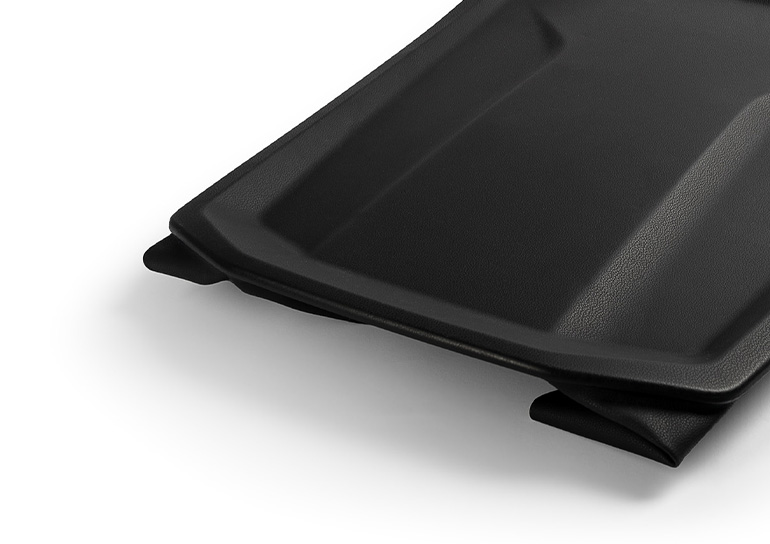

Tailgate

Speacker

Seats

Interior visible parts

Pedals

Mirror

Batteries, Cover and Eletric Box

Houseware

Grills

Filters

Door Panels

Dashboard

Cover Wheel

Cable Guidances

Chrome

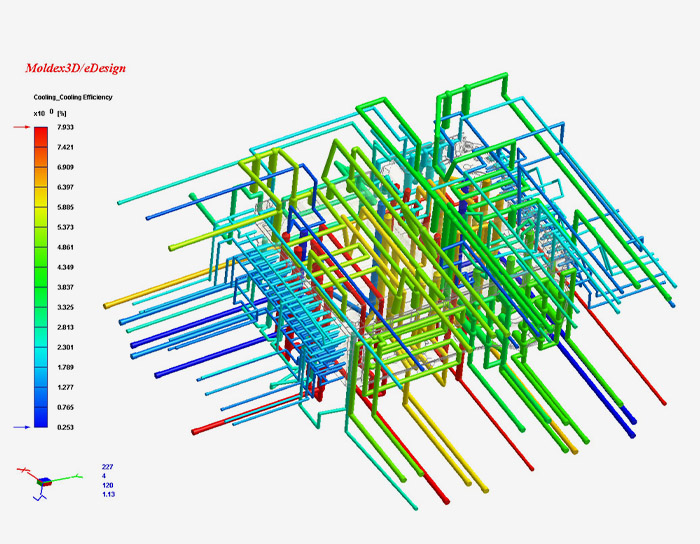

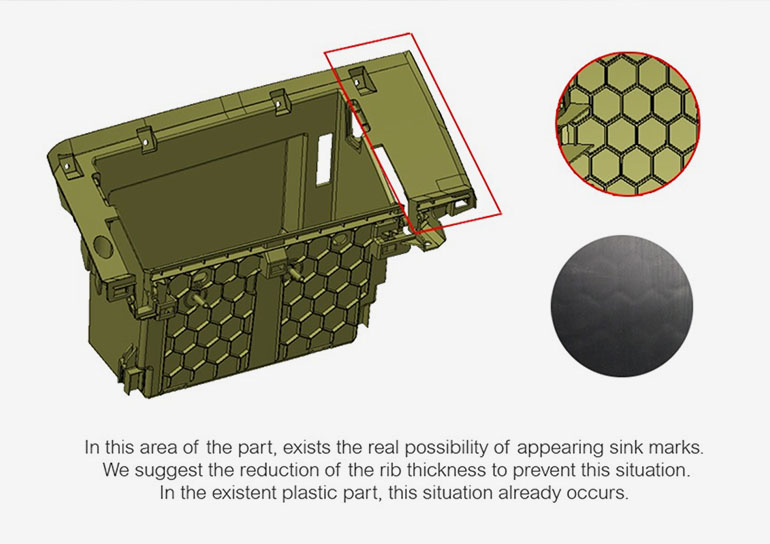

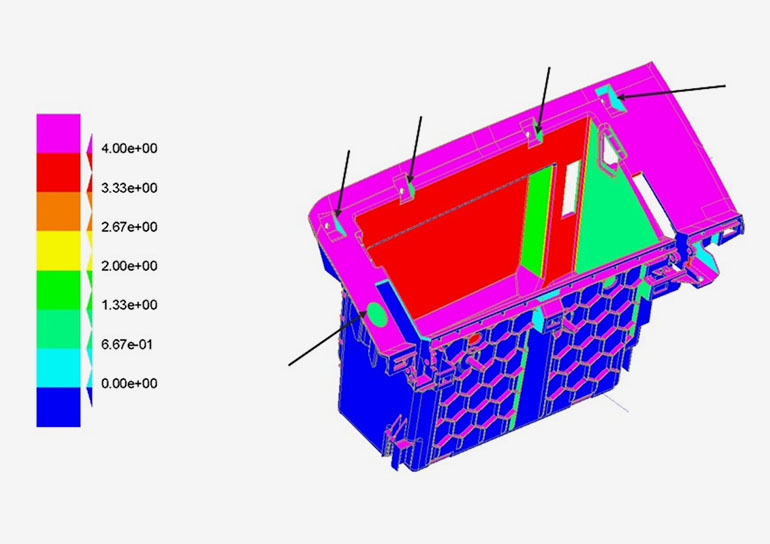

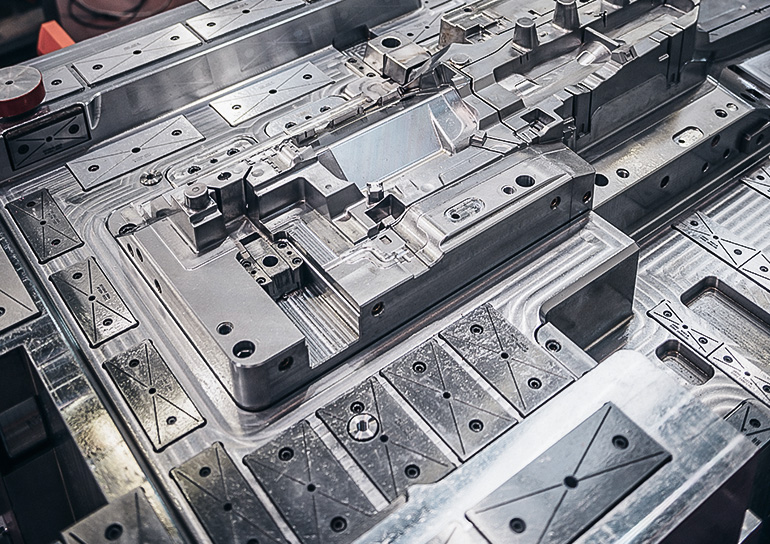

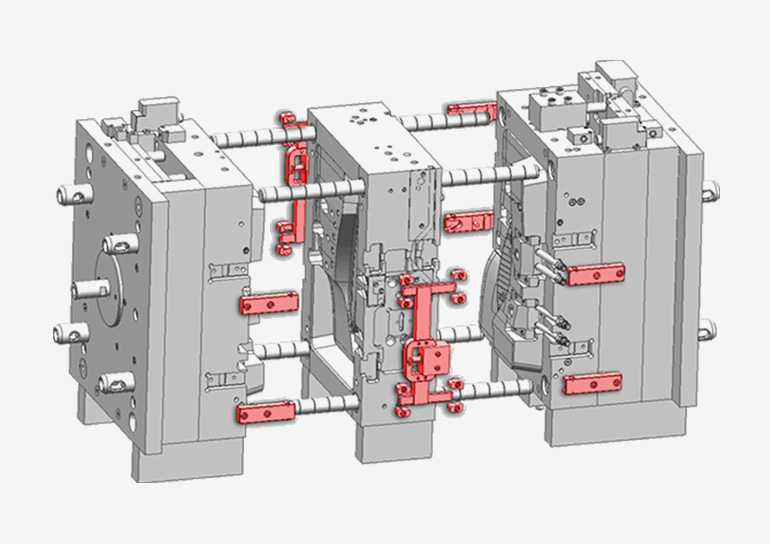

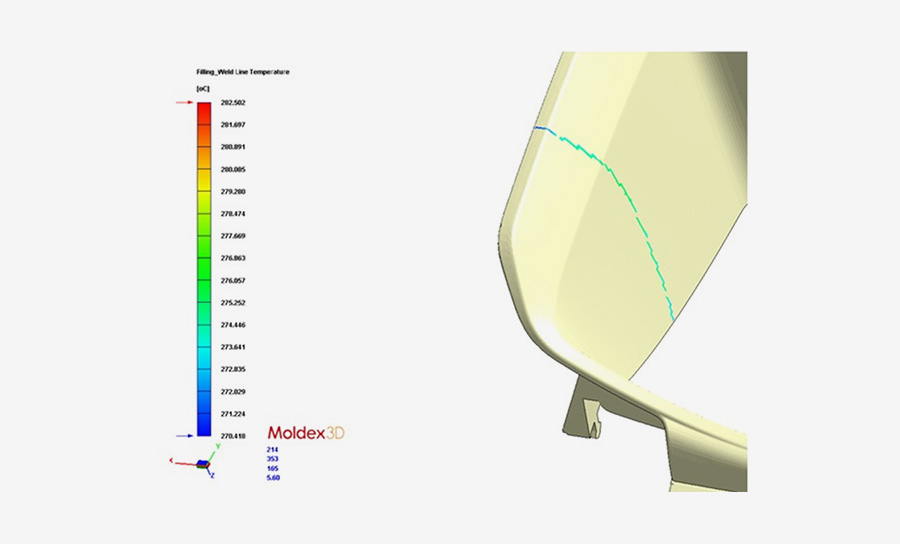

Design and Engineering

Our Engineering Department, with an extensive knowledge on industrial and plastics processes, assures the design and development of each project, accepting all the challenges and always presenting the best solutions for different and new technologies.

Planning SBI

DRT has its own internal management system, fully developed inhouse – SBI (Sistem of Business Intelligence). SBI consists of a MES software – Manufacturing Execution System – focused on the planning, execution and control of the company’s operation, covering the commercial, production, quality, human resources/infrastructure processes, among others.

In this way, as the core activity of DRT Advance is based on optimizing, digitizing and interconnecting the operation and resources of the company,it is possible to systematically update and follow the progress of all stages in each project.

Prototyping

Rapid Prototyping plays a basic role in the initial phase of each project. This area was created to complete the range of services to our customers. The possibility to check the functionality of each part, the guarantee of the fastest time-to-market and the cost reduction of the project are of such significance, that today all the projects with ambition use Rapid Prototyping and Rapid Tooling.

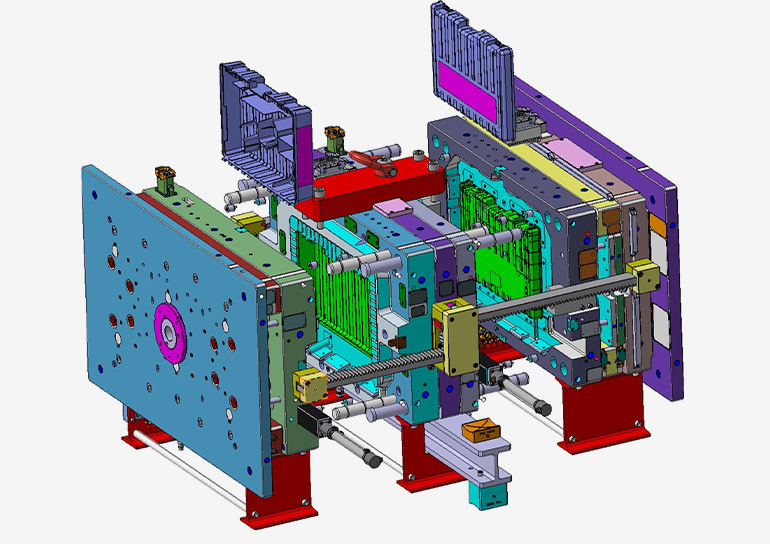

Technologies

- Stack Mould;

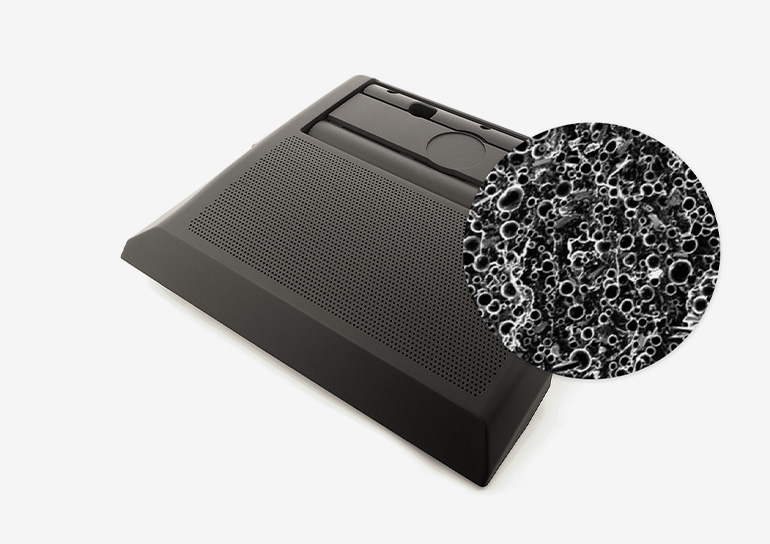

- MuCell;

- Tandem;

- GID;

- 2K and Multi component;

- Overmolding – insert mould, Over textile, foam moulding;

- Vario-cooling;

- IML;

- Injection compression.